March 27, 2024

Master Craftsmen Unveiled: Exploring What Does a Millwright Do

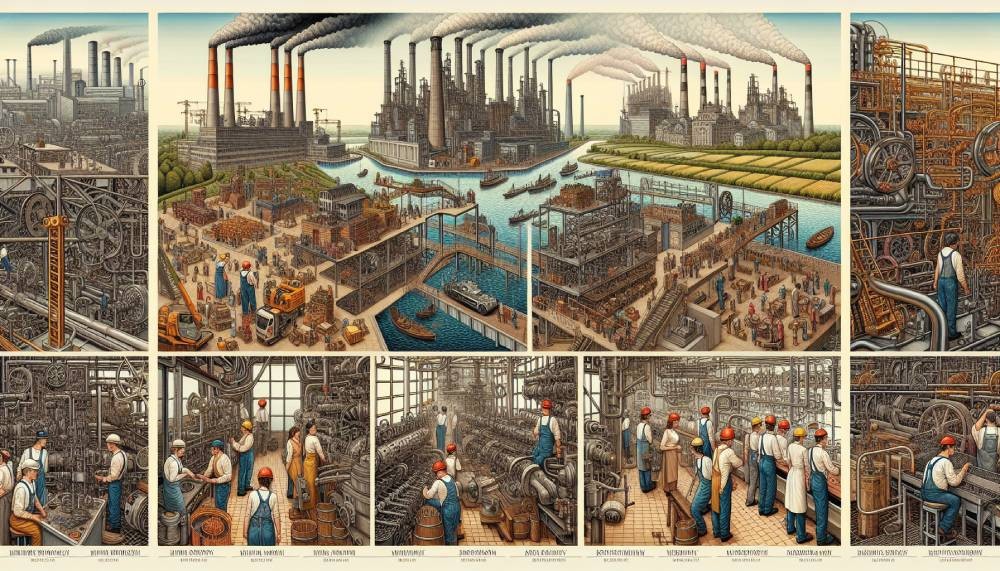

If you’ve ever wondered, “what does a millwright do?”, their role centralizes around precision and power. Tasked with installing and maintaining industrial machinery, a millwright is a key player in ensuring operational continuity. This article unfolds the diverse duties that define a millwright’s day-to-day work, from exact alignments to critical repairs, each vital to the industrial landscape’s heartbeat.

Key Takeaways

- Millwrights play a crucial role in industry by installing, maintaining, and repairing machinery, ensuring operational efficiency and safety in diverse environments such as construction, manufacturing, and mining.

- A millwright’s skill set is consistently evolving, requiring formal apprenticeships, certifications, licensing, and ongoing education to keep up with technological advancements and maintain a competitive edge.

- The job market for millwrights is robust with projected job growth and competitive salaries that reflect experience, location, industry demands, and the complexity of the machinery they work with.

The Essential Role of a Millwright

Millwrights are the cornerstone of operational efficiency in industrial settings, wielding their expertise to keep machines running like clockwork. Their millwright job description encompasses a vast array of responsibilities, from installing hefty turbines to precision-aligning conveyor belts and conducting thorough inspections to stave off potential malfunctions.

With an extensive knowledge of industrial mechanics and the use of power tools, millwrights work diligently to ensure that every gear and shaft functions to its full potential, minimizing downtime and maximizing productivity.

Machinery Alignment and Installation

The process of installing machinery calls for a millwright’s precise touch, especially on construction sites where the alignment of heavy machinery can make or break a project’s success. They rely on advanced technologies such as robotic stations and laser alignment systems to achieve the exactitude required for complex machines to operate at peak efficiency.

By setting benchmarks for machine tolerances, millwrights lay the foundation for industrial operations to run smoothly, safeguarding against costly errors and ensuring the longevity of machinery, including milling machines.

Repair and Maintenance

Imagine a world where machinery never falters—millwrights strive to make this a reality through diligent maintenance and repair. Their work prevents machinery malfunctions, thus avoiding the cascade of issues that arise from worn parts and misalignments, as well as unplanned production halts and potential injuries.

With a proactive approach to maintenance, these skilled tradespeople maintain machinery with such precision that they extend its lifespan and uphold the stringent standards expected in industrial settings.

Precision Fitting and Welding

Precision fitting and welding are not just tasks but art forms for professional millwrights. It’s a discipline where every millimeter matters, as the smooth operation of industrial machinery hinges on the exact fitting of components like bearings and gears. These highly skilled tradespeople ensure that each component melds flawlessly with the next, utilizing specialized tools and strict adherence to industry practices to prevent malfunctions and ensure efficiency.

Millwright Specializations

Millwrights are not bound to a single industry; their skills traverse a multitude of sectors, each with its unique challenges and requirements. From construction sites to manufacturing plants and beyond, millwrights adapt their expertise to fit the specific needs of their work environment. Whether it’s the intricacy of robotics or the ruggedness of mining operations, these professionals stand ready to tackle the tasks at hand with specialized tools and an unwavering commitment to quality.

Construction Millwrights

Construction millwrights are the driving force behind the seamless setup and installation of machinery at job sites. Their realm extends from power plants to factories, where they manage not just the installation but also the repair and maintenance of equipment. Employing an arsenal of precision tools and heavy equipment, they ensure that from the first bolt to the last conveyor belt, every component is positioned and functioning correctly, often under the pressure of tight deadlines and the physical labor that comes with working as a construction millwright in such dynamic environments.

Manufacturing Plants

Within the walls of manufacturing plants, millwrights are instrumental in the orchestration of assembly lines and conveyor systems. They work amidst the hum of complex machinery, ensuring that every new piece of equipment is installed with precision, contributing to the high-quality output of products. Adherence to exact tolerances is not just a requirement but a hallmark of their trade, underscoring their role in upholding the manufacturing industry’s standards.

Mining Operations

In the demanding world of mining operations, millwrights are tasked with the upkeep of robust machinery that delves deep into the earth. They maintain and repair equipment like turbines and generators, performing regular inspections to guarantee safe and efficient operations.

The rugged terrain of mining sites presents unique challenges, met with the resilience and expertise of these skilled tradespeople.

Robotics and Automation

As industries pivot towards automation, millwrights skilled in robotics are finding their expertise in higher demand than ever before. The advent of computerized systems and the robotization of factories require millwrights to possess not only mechanical knowledge but also an understanding of software programs and basic programming. These advancements open new avenues for millwrights, who are now integral to the seamless integration of these technologies into industrial operations.

Becoming a Professional Millwright

Embarking on the journey to become a professional millwright is an adventure in itself, blending rigorous training with hands-on experience. The path to mastery in this skilled trade involves formal apprenticeship programs, a dedication to continuous learning, and the pursuit of certifications that validate a millwright’s expertise.

With a strong foundation in industrial mechanics and a resume fortified by mechanical work experience, aspiring millwrights can navigate their way to a successful career in this dynamic field.

Training and Apprenticeships

The cornerstone of a millwright’s education is the apprenticeship program, a blend of classroom instruction and practical, on-the-job training that spans three to four years. Apprentices learn to dismantle, erect, and repair machinery, gaining skills that are in demand across many industries. With each passing year, their expertise grows, and they earn their stripes—along with pay increases—culminating in their journeyman status, ready to take on the world of industrial mechanics.

Certifications and Licensing

A millwright’s toolbox is incomplete without the certifications and licenses that underscore their proficiency and adherence to industry standards. From welding to forklift operation, each certification opens doors to new opportunities and showcases a millwright’s commitment to excellence.

Advanced certifications, reflecting leadership or specialized machinery operation, further propel millwrights along their career trajectory, ensuring they remain at the forefront of their trade.

Continuing Education

In an ever-evolving industry, millwrights must stay abreast of the latest technologies and methodologies. Continuous education is not just recommended but essential for millwrights who wish to remain relevant and competitive.

As industries adopt advanced control systems, millwrights supplement their mechanical prowess with technical knowledge, preparing themselves to tackle the challenges of tomorrow’s industrial landscape.

The Millwright Workplace

The workplace of a millwright is as varied as the machinery they tend to. From the sweltering heat of a steel mill to the precise environment of an automotive assembly line, millwrights adapt to different job sites with resilience and skill. They adhere to rigorous safety protocols and collaborate with a diverse range of professionals, ensuring that each project is not just completed, but mastered.

Job Sites and Settings

Millwrights are the nomads of the industrial world, often traveling to various settings where their skills are in demand. They may find themselves in the heart of a bustling factory or within the complex infrastructure of a power plant. Regardless of location, their responsibility to maintain machinery and equipment is paramount, ensuring that the wheels of industry keep turning.

Safety Protocols and Procedures

In an occupation where precision is paramount, safety is the creed by which millwrights operate. Donning hard hats and steel-toed shoes, they enter work environments with a deep awareness of the hazards that accompany their trade. By maintaining strict adherence to safety protocols, millwrights not only protect themselves but also ensure an accident-free work environment, a testament to their professionalism and the safety standards upheld by the industry.

Collaborating with Other Professionals

The role of a millwright, and those who provide millwright services, is steeped in collaboration, requiring them to work in concert with other professionals. Whether consulting with engineers on the technical specifications of machinery or strategizing with maintenance crews on preventative measures, millwrights are team players.

Their ability to communicate effectively with machinery operators and other skilled tradespeople is crucial in maintaining operational efficiency and achieving project success.

Millwright Salaries and Job Outlook

A career as a millwright not only offers the satisfaction of hands-on work and problem-solving but also a stable and potentially lucrative job market. The salary of a millwright can vary widely based on experience, location, and industry. However, with job growth on the rise, those who wield the tools and knowledge of this trade can look forward to a future where their skills are not only needed but well-compensated.

Average Salary and Hourly Wages

The financial rewards of a millwright’s labor can be substantial, with the average salary ranging from $50,000 to $70,000 annually. Entry-level millwrights and apprentices earn competitive starting salaries, and as they ascend through the ranks of experience and expertise, their earnings can reflect their growing value in the industry. This steady climb is a clear indicator of the respect and demand for the technical skills that millwrights bring to the table.

Factors Affecting Millwright Salary

The earning potential of a millwright is influenced by a mosaic of factors. Geographic location plays a significant role, with salaries adjusted for the cost of living and demand for skilled tradespeople in different regions. Additionally, the nature of the job duties, whether it involves working with advanced machinery or in particularly hazardous conditions, can also affect hourly wages and overall compensation.

Job Growth and Demand

Opportunities for millwrights are expanding at a brisk pace, with a projected job growth of 13% over the next decade. This upward trend speaks volumes about the essential role millwrights play in the industrial sector and the high regard in which their skills are held.

With a significant number of job openings expected each year, millwrights can look forward to a future of solid employment prospects and the continued necessity of their specialized expertise.

Summary

From the intricacies of aligning precision machinery to the grandeur of constructing industrial giants, the millwright’s craft is an amalgamation of skill, dedication, and technical acumen. As industries evolve and technology advances, the millwright’s role becomes ever more critical, promising a bright future for those who choose this path. For those with a penchant for problem-solving and a desire to shape the industrial world, a career as a millwright offers not just a job but a lifelong journey of growth and accomplishment.

Frequently Asked Questions

What are the main duties of a millwright?

The main duties of a millwright include assembling, setting up, and repairing complex mechanical equipment in industrial and construction settings, making precision crucial to avoid strain or misalignment that could harm the machinery.

What is the top salary for a millwright?

The top salary for a millwright can reach up to $83,690 annually, with an average salary of $60,330 reported. These figures can vary based on factors such as experience and location.

What does a millwright really do?

A millwright is responsible for the installation, maintenance, repair, and reassembly of machinery in industrial and construction settings. Their precise work ensures the performance, longevity, and safety of machinery and operations.

What skills do you need to be a millwright?

To be a millwright, you need skills such as machinery repair, problem-solving, industrial mathematics, communication, attention to detail, mechanical skills, and the ability to read tables, drawings, and specifications. These skills are essential for maintaining and repairing machinery effectively.

Can millwrights specialize in certain industries?

Yes, millwrights can specialize in various industries such as construction, manufacturing, mining, and robotics, tailoring their skills to the specific requirements of each sector.